Precast Concrete Products

Pre-stressed Concrete Products

Precast Concrete Products

Precast concrete products are factory-made elements which are manufactured with concrete in a pre-engineered mold, treated and cured in a controlled factory environment, transported and erected in project site.

Why precast Products

The primary advantage of using precast concrete products compared to traditional Cast in place construction is speed and reduced cost of construction. Also, Precast offers outstanding quality, Sustainability, No formwork needed at site and reduced construction related safety risks.

The product portfolio comprises of various types of precast or pre-stressed products such as:

Foundations

Bucket Foundation: Precast Bucket foundations realize the site-work faster and cheaper. Indeed, cast on-site buckets need rather complex molding and reinforcement, and working conditions are more unfavorable. It may be used only in conditions of firm and level ground. Buckets sometimes have dowels and base plate is cast on site or whole unit can also be precast.

Columns

Precast Columns can be single-tier or multi-tiered as required. Use of precast columns will expedite the project, as there is no requirement to wait for the curing time in order to reach the required strength as there is with cast-in-situ columns.

Column connections are often made using bolted or socket connections with foundations.

Link for Columns loading tables

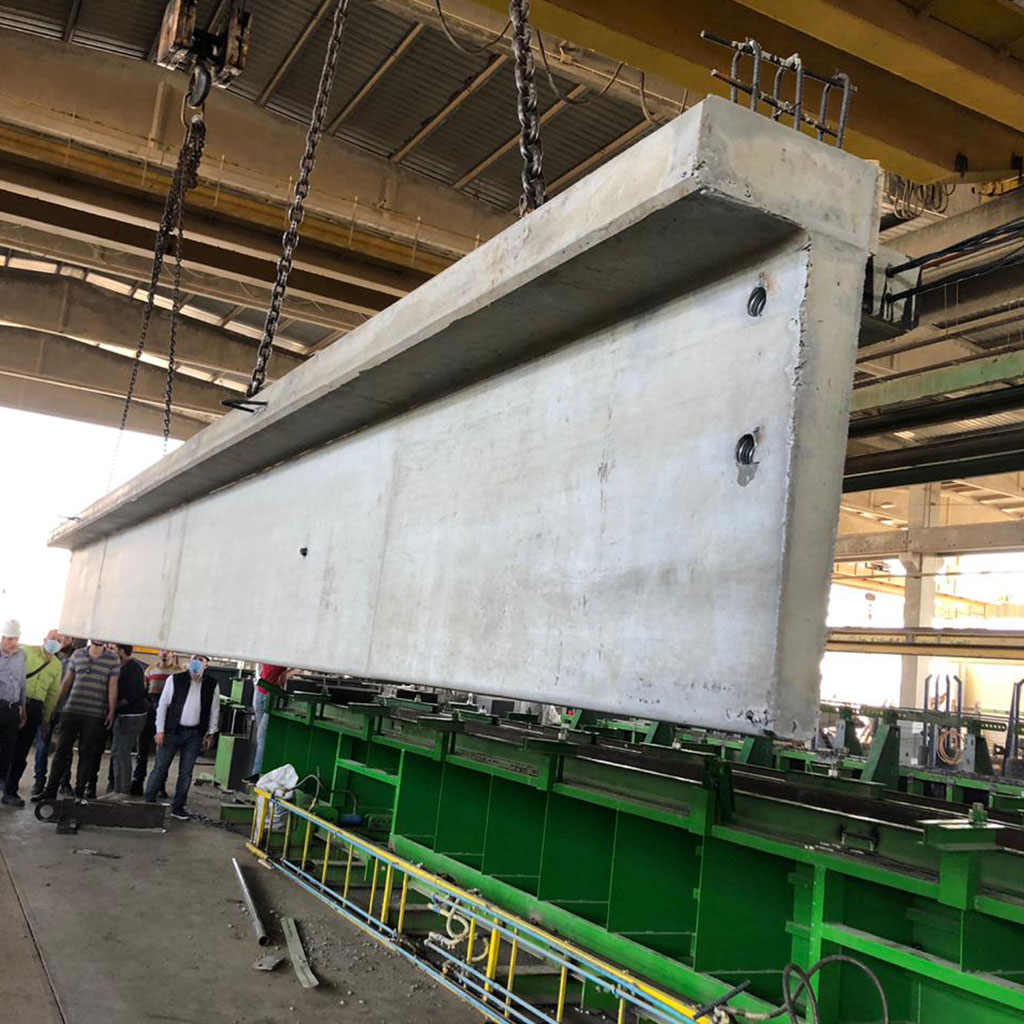

Beams & Rafters

Precast Beams provide a flexible solution to the structural component of your project. Precast Beams can be used for a number of applications from parking structures to the structural framework of commercial buildings. Modern concrete has various types of concrete beams such as Normal reinforced concrete beams for traditional and residential buildings, Prestressed beams for Halls and garages and Delta beam for industrial hangers.

Wall Panales

1.4.1 Insulated Panels: Insulated precast concrete panels consist of two concrete layers joined by shear connectors with an insulating layer between them. The insulation layer is continuous over the entire surface area without any thermal bridges and its thickness is determined by the insulation value required. The thinner external layer can be made in a variety of concrete colors and surface treatments while the internal, often load-bearing layer is normal grey concrete. Insulation of walls reduces both construction cost and operating cost.

- The Developer benefits through reduced initial investment for the cooling/heating systems.

- The Owner / Resident benefit through reduced electricity consumption.

1.4.2 Cladding Panels: Precast concrete panels are reinforced concrete units available in a wide range of mixes, colors and finishes. Finishes can include smooth, acid-etched, or sand-blasted. Concrete Mixes designed to resemble natural stone can also be produced. Highly articulated designs can be accommodated by the moldable concrete mix.

Load & Non-Load Bearing Panels

Precast concrete panels are reinforced concrete units available in a wide range of mixes, colors and finishes. Finishes can include smooth, acid-etched, or sand-blasted. Concrete Mixes designed to resemble natural stone can also be produced. Highly articulated designs can be accommodated by the moldable concrete mix.

Soild Slabs

Solid Slabs are fully customizable concrete slabs of varying width, length and thickness. Solid Slabs can be designed and produced with mild reinforcing or by adding prestressing strands. They can be used in a variety of applications such as bridges, piers, building floors, roof systems, detention vault lids and boat launches. Solid Slabs can be cast with specialty inserts for lifting, mounting or connecting hardware. They can be produced with smooth, broom or raked finishes.Highly articulated designs can be accommodated by the moldable concrete mix.

Prestressed Products

With same quality and speed of precast products, when high loaded, large spans floors or stadiums risers are required , the prestressed floor elements (hollow core slabs , double tee slabs , beams , bleachers,… ) are the optimum , fastest and most effective solution compared to cast in place construction

Pre-stressed Concrete Products:

Hollow Core Slabs

Pre-stressed precast hollow core slabs are the most widely used type of precast flooring. The system offers numerous benefits to engineers and architects because it gives maximum strength with minimum weight, versatility in span / depth ratio, a smooth soffit and a high speed of erection leading to an economical way to construct floors.

Modern Precast manufactures a full range of hollow core slabs with thicknesses ranging from 120mm to 500mm, with longest spans up to 20 meters. For further details: