FACTORIES MACHINERY, COMPLETE TURKEY INDUSTRIAL PROJECTS

About

Modern Construction Group (MCG) was founded in 2015 out of the need for a specialized construction arm for Modern concrete and suddenly become one of Egypt’s Reputable companies when it comes to Specialized Construction work, not only MCG Executes work related to precast Elements as successor and predecessor works also MCG executes all related to factories machinery, complete turnkey industrial projects.

Mission

MCG is dedicated to introducing the highest quality yet with value engineering when it comes to Industrial construction services and Specialized contracting such as precast and prestressed concrete all that is to be done with competent staff and professionalism into fulfilling this Mission and customer satisfaction.

Vision

MCG aims to spread the culture of quality and value-engineered work and be recognized as one of Egypt’s first-class pioneer companies, working to expand our knowledge and people all over Africa.

scope

MCG specializes in industrial and administration projects, whether multi-story or has a very complex structure system, and works to complete the precast building’s construction by working at the site for Modern concrete by the connection of being a sister company for it.

Foundation

(RC, Special RC footing):

RC foundation is the essence of every project especially industrial projects which has high loads, MCG goes through earthworks seriously and has a well-trained staff to cast the concrete especially that related to machinery installation or precast concrete erection of work.

Water Treatment plants and Tanking systems

(Full construction project):

When it comes to water treatment plants MCG has an experience with 5 complete water treatment plants and over 25 under or above-ground tanks, Industrial and Sewage treatment is a type of wastewater treatment that aims to remove contaminants from sewage to produce an effluent that is suitable to discharge to the surrounding environment or an intended reuse application, thereby preventing water pollution from raw sewage discharges, MCG had the opportunity to give back to the community and contributing into creating less polluted work environments.

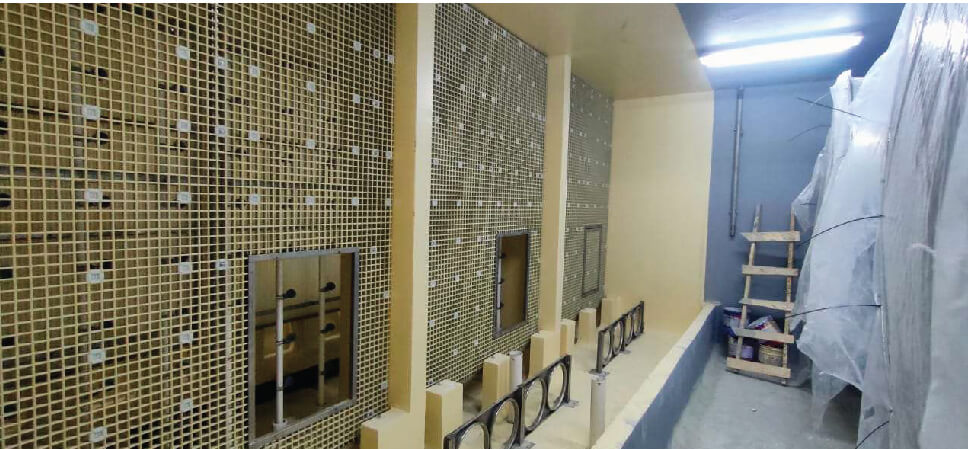

Technological Concrete Related work

MCG studies prior work on every element isolation requirement whether it’s a high chemical area or high temperature or special waterjets through using new and innovative chemicals from world-recognized companies such as SIKA and DBASF EITHER CEMENTIOUS OR POLYURETHANE and have the ability to handle UV if exposed of course alongside with the traditional Bituminous and Polypropylene (Kartonal) Boards.

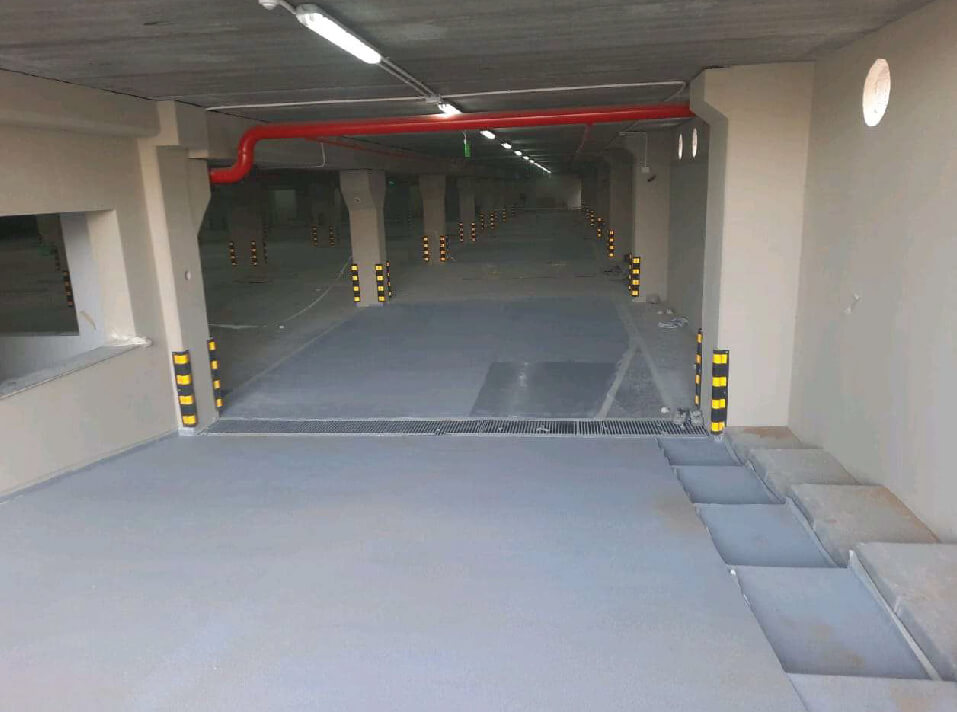

Drainage Networks:

MCG had a big experience regarding the DRAINAGE Networks either Industrial or domestic or Sewage and the tie-up connection to the main treatment plant including the inlet and outlet for every pipeline and the testing “Air pressure or water pressure “, MCG had Dealt with (VCP “Vitrified Pipes”, UPVC, Stainless steel, all PVC items and fittings in addition to the Manholes, gully traps, and the inspection chambers).

Flooring Systems (S.O.G & Topping ) & Special Tie Up to precast systems :

Given the fact that industrial projects require an innovative yet precise solution for flooring, MCG had been introducing upgraded solutions and techniques throughout the years also for Topping and connection systems with beams and other precast elements in order for most precast buildings to work with structure systems as one.

Quality Management System & HSE:

- MCG has a Quality Management System in accordance with ISO 9001, certificates must be valid throughout the project duration.

- All Quality Procedures must be followed during all stages of Pre-Casting, Site casting, and repair works of the elements according to approved ITP and Method statements.

- MCG has a wide range of forms and preventative procedures.

- All materials involved in producing elements will be tested frequently according to ECP203-2020 tests frequency and standards.

- Quality plan shall cover all required check procedures and reports are performed as required in all work stages.

- Q.C engineer will check every element during shuttering and reinforcement bars preparation, and fill out the related checklist form.

- The objective Zero Accident Philosophy ZAP is the main target in all work procedures, to reach this target, safety procedures shall be followed strictly and risk assessment for every stage of work will be evaluated frequently according to the safety plan.

- Basic PPE shall be worn by all employees and special workers may need extra safety equipment according to the safety plan.

- Working place must be clean and tidy.

- All safety supervisors must be qualified to deal with any accidents.