Our Precast Concrete Flexible System

Doesn’t have space!!! …. Why don’t go vertical?!!!!!!

One of the biggest challenges for any owner is he doesn’t have any horizontal space left, MCC had this issue with one of the clients and has conducted a solution that committed to the same area with vertical expansion from a one-story Hall to 3 stories hall. Which had solved all the client’s requirements (Parking lot, 2 floors for factory expansion)

Why precast for vertical expansion?

When we come to vertical expansion we go for precast for those reasons:

TIME FACTOR:

Of course, shutting down an already-running factory has many challenges when coming to the time frame, the client needed to get the job done as soon as possible. MCC fulfilled its duties by working on parallel stages (Old Hall Disassemble, Piles and retaining wall, footing, Precast elements fabrication, and Precast Erection) all of which had been executed with minor time frame lag between activities that all stages were almost running together in parallel. This has given MCC the edge of time factor and has the satisfaction from the owner to get his Hall fully and running from disassembling to commissioning within Months!!

Value Engineering:

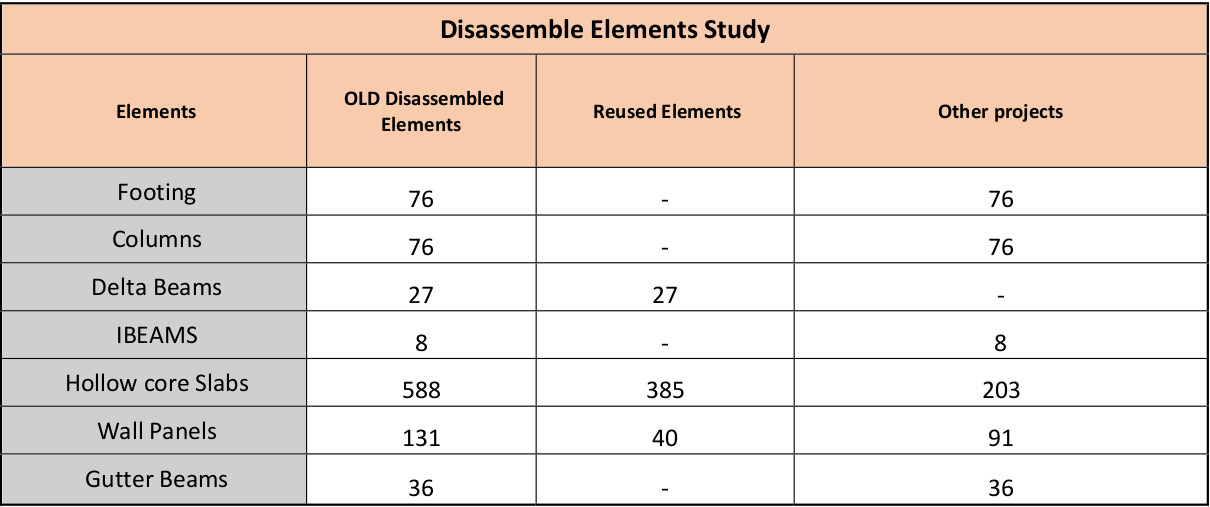

MCC conducted a thorough value engineering study that when it comes to cost has a complete study as follows.

- So cost impacts were taken into consideration for this unique project and case.

- Almost 100 % of elements were rearranged and used in this project or owner-related projects

- Concrete and steel scraps were utilized in recycling for other industries, believing in the process of a less polluted environment.

- Cumulative area and span-free columns areas

- Initially The hall was about 5800 m2 converted into almost 17400 m2 Hall as follows:

- Basement (Parking lot 5000m2 +800 m2 car wash and archive)

- First floor (2900 m2 machinery +2900 m2 stores)

- Second floor (2900 m2 Admin area +2900 m2 Sampling area)

This had given the client triple the area without having to go with any other moving or further decisions.